How does a mechanical watch work?. How does a mechanical watch work?. How does a mechanical watch work?. How does a mechanical watch work?. How does a mechanical watch work?

How does a mechanical watch work?. How does a mechanical watch work?. How does a mechanical watch work?. How does a mechanical watch work?

How does a mechanical watch work?

by Christophe Roulet

A watch that gives the time: great. A watch that gives the exact time: fantastic. A mechanical watch that goes on giving the exact time for decades: downright amazing.

Amazing

Some of the greatest scientific and technical minds have spent centuries perfecting the mechanical watch, making it more reliable, more resistant and more ergonomic. Almost eternal, you could say. A mechanical watch has no need for batteries, no need to be plugged in and recharged. It is entirely self-sufficient. Take good care of it, and it will be your friend for life: solid, punctual and for ever by your side.

Machines that give the time

But what exactly do we mean when we describe a watch as “mechanical”? From the fourteenth century, excluding clepsydras and sandglasses, the instruments that divided and measured time were conceived of as “machines”. From vast assemblies of cogs and gears inside towers, to pocket-sized, to their current home on the wrist, these “machines” have undergone a succession of technical developments, although their basic principle is unchanged, using mechanical power from a spring or a weight to function. The mechanical watch forms a separate category to electronic quartz watches and, more recently, smartwatches that run off a battery (which can or cannot be recharged) and are controlled by a microprocessor.

Six organs

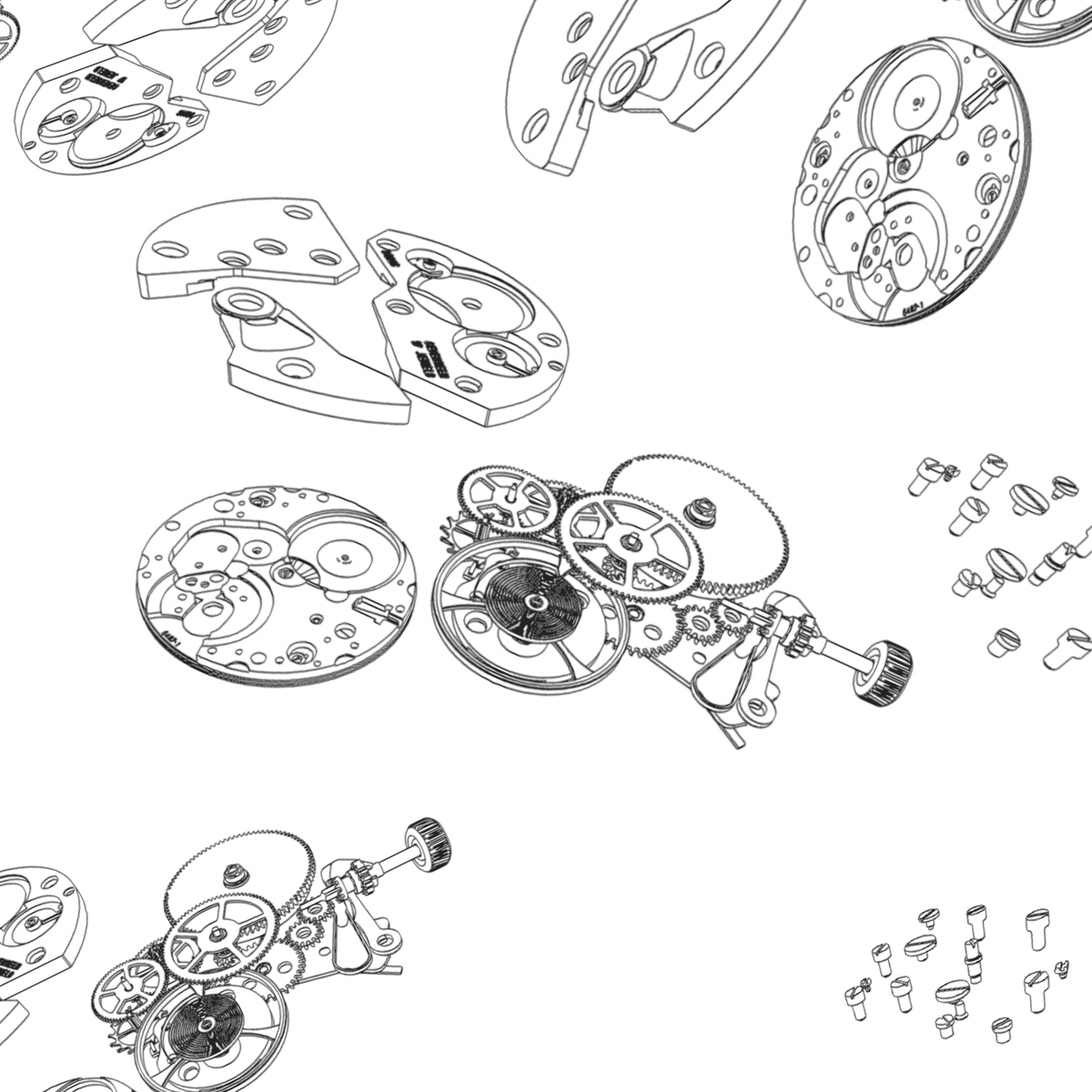

In the same way a car’s internal combustion engine transforms fuel into the rotary power that drives the wheels, a mechanical movement runs off power that flows through a “chain”. This chain, which begins with the power store and ends with the time display, is the same in every mechanical watch, from the most basic to the most complex. If the hour, minute and (where applicable) seconds hands are to rotate at the correct speed, the flow of power through this chain must be controlled. Therein lies the magic of a mechanical movement, whose 130-some parts (for a basic movement) must be perfectly orchestrated to display time with the greatest possible precision. A mechanical movement is generally subdivided into six units, each of which performs a specific function within the chain. They are:

- Winding mechanism – the crown winds the movement and sets the hands

- Barrel – the barrel stores power from the mainspring

- Wheel train – the wheel train (or gear train) transmits power

- Escapement – the pallet fork and the escape wheel distribute power

- Regulator – the balance and balance spring regulate power

- Display – hands indicate the time and any other functions

Accumulating power

For a watch to function, it needs power. In a mechanical watch, this power is supplied by a spring (the mainspring) contained inside a cylinder called a barrel. For the mainspring to produce power, it has to be wound. This is the job of the winding mechanism in a hand-wound or manual-winding movement, and the oscillating weight or rotor in an automatic or self-winding movement (another word for movement is “calibre”). Turning the crown back and forth (manual winding), or wearing the watch so that the natural motion of the arm causes the rotor to freely rotate (automatic winding), will gradually wind the mainspring. The crown also serves a second purpose, which is to set the hands. When the crown is pulled out, the winding mechanism connects with the hand-setting mechanism.

Storing power

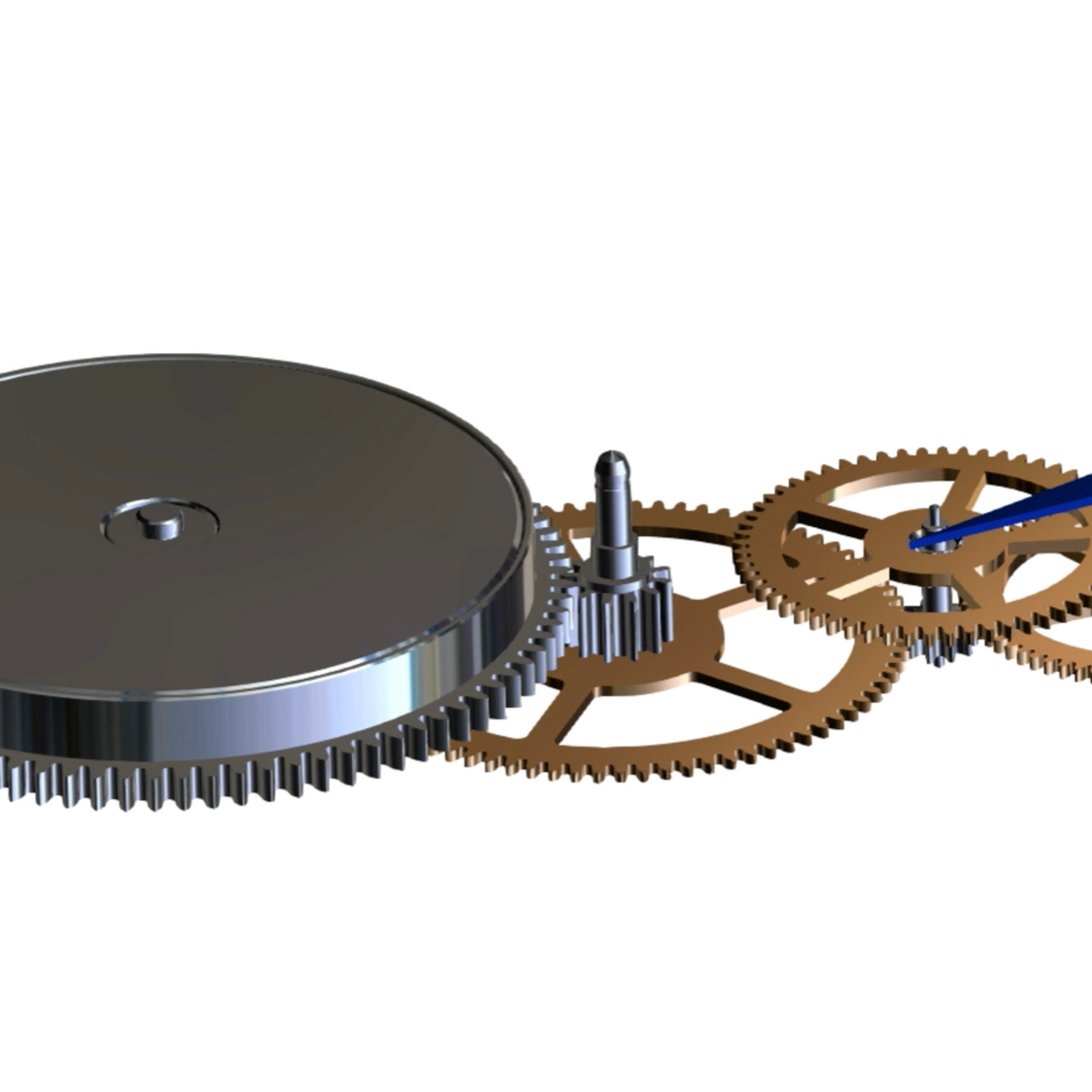

Power is stored in the barrel, which is a cylindrical component that contains the mainspring. As the wound mainspring unwinds, it rotates the barrel. This rotation is transmitted through the wheel train.

Transmission

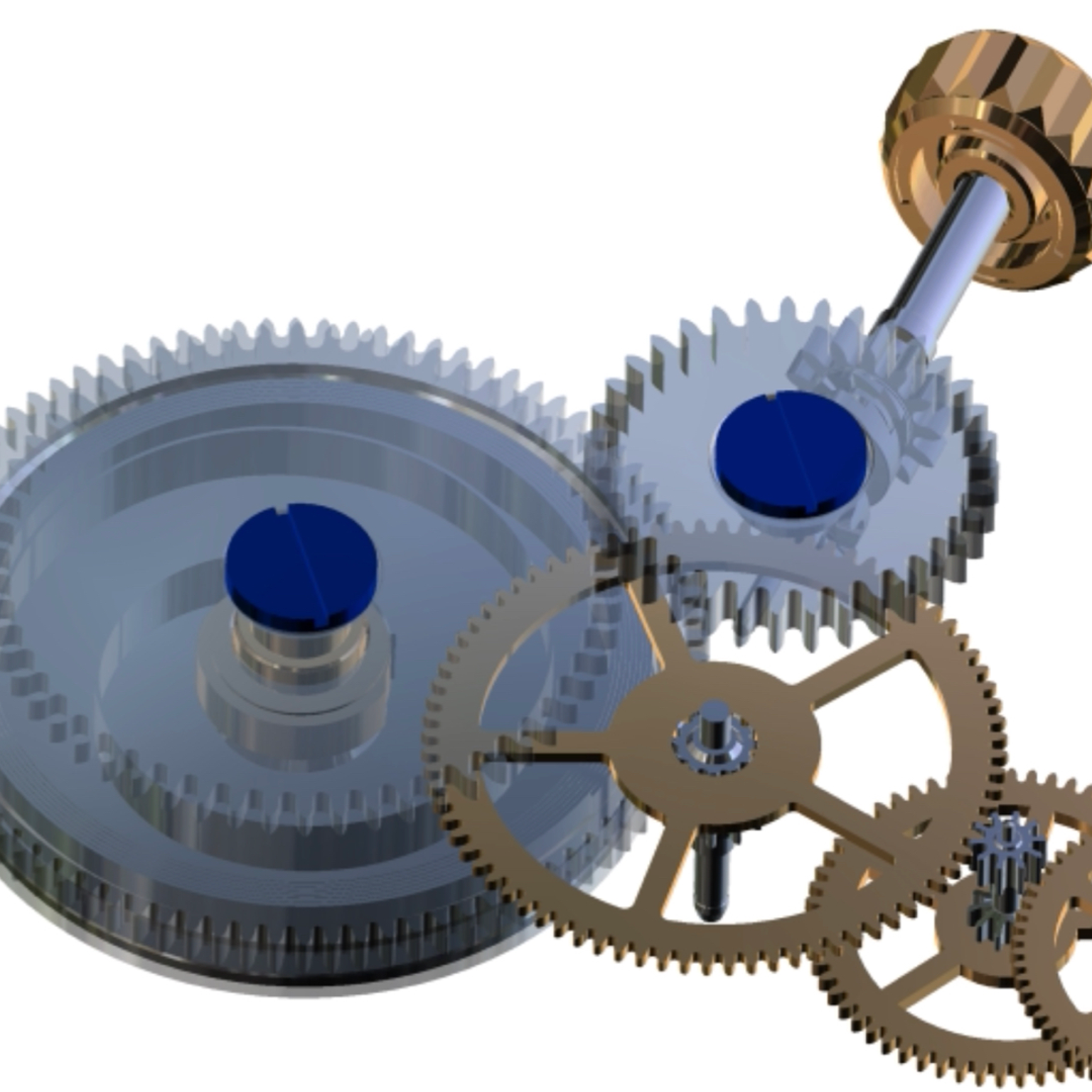

The wheel train (or gear train) is responsible for the transmission of power. This wheel train is composed of a series of wheels. Each of these wheels has a toothed rim and central pinion. As one wheel meshes with the next, this increases rotational speed by a ratio that is determined by the different diameters of the wheels and pinions. These different rotational speeds establish the speed at which the hour, minute and seconds hands rotate around the dial.

Distribution

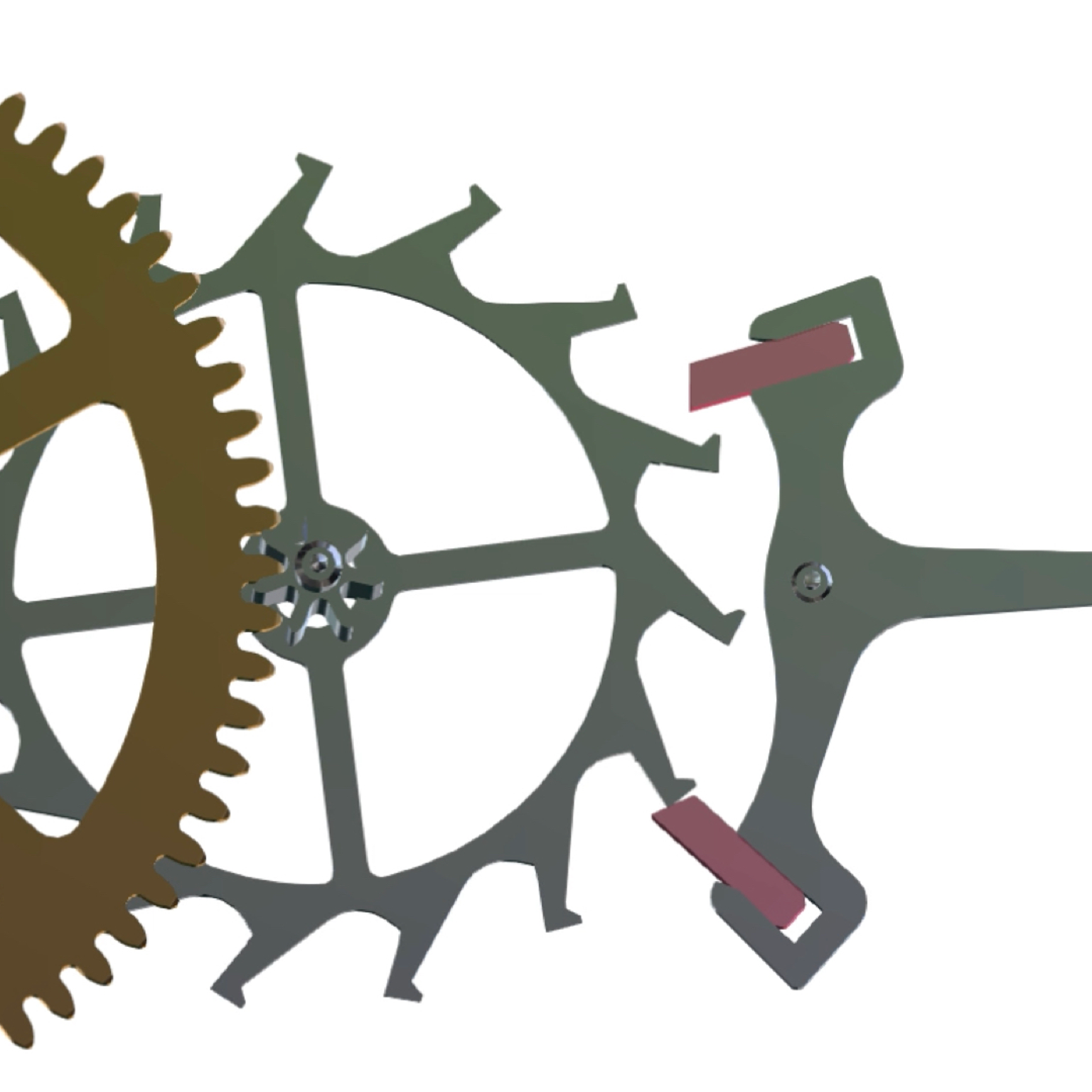

After power has been produced, stored and transmitted, the serious stuff begins! In the next stage, the continuous flow of power from the barrel is transformed into metered increments, in much the same way each beat of the heart sends oxygen-rich blood to the organs. This transformation of linear force into impulses is the role of the escapement, which distributes energy. The escapement releases power in regular portions so that the time can be divided and measured. Without the escapement, the mainspring would unwind within seconds - like the spring in a pull-back toy car.

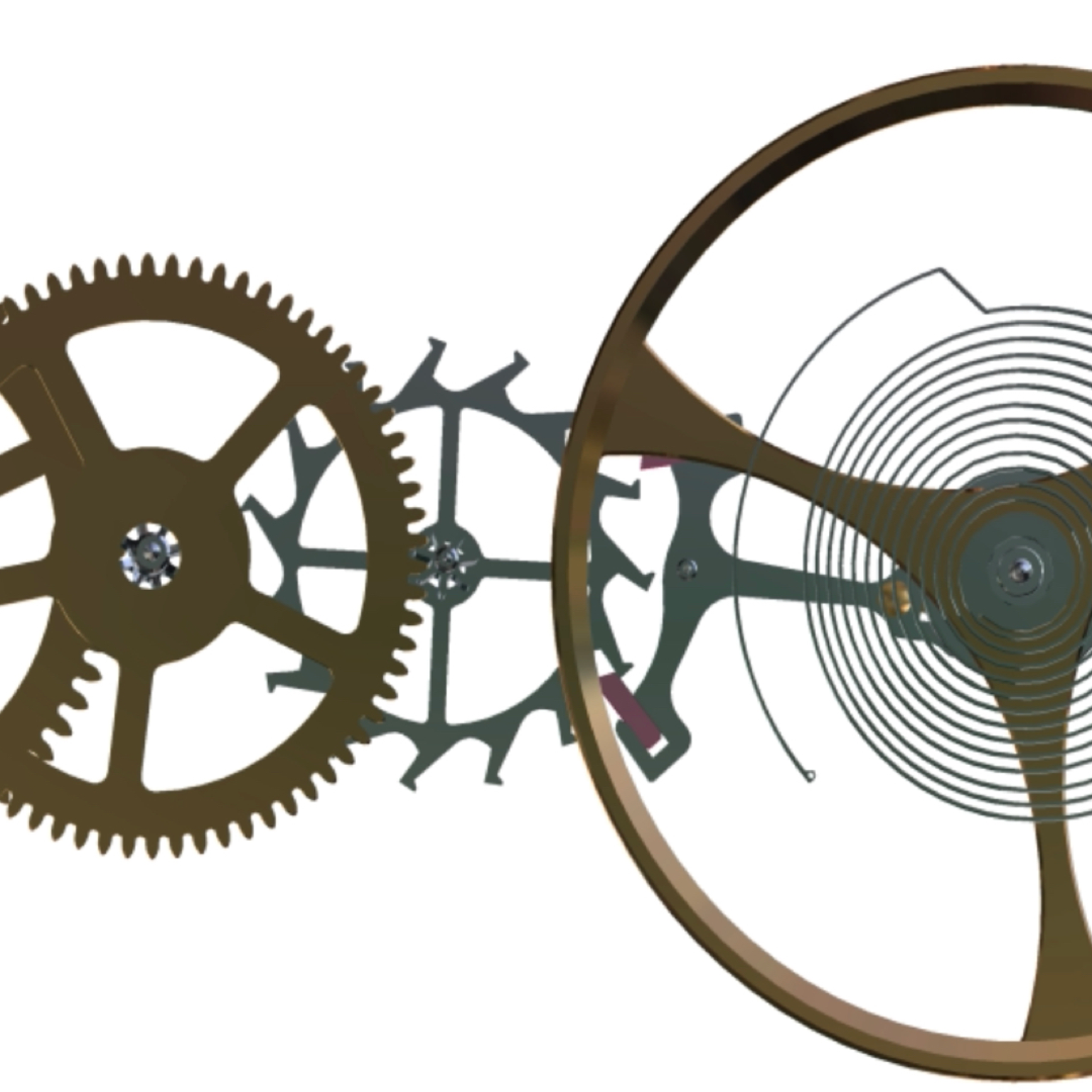

The escapement is composed of an escape wheel (connected to the wheel train) and a pallet fork, which has two arms at one end and a fork at the other. As the pallet fork pivots, it controls the rotation of the escape wheel via its two arms which lock then release one tooth of the escape wheel (which makes the watch’s ticking sound). This divides the escape wheel’s rotation into sequences. Each sequence becomes a portion of time.

Regulation

If the movement is to divide time into precise units, power must be distributed in regular portions. For this reason, the forked end of the pallet fork interacts with the balance and spring, which form the regulator or oscillator. The balance is a wheel whose staff is fitted with a very fine spring known as a balance spring or hairspring. The escape wheel pushes the pallet fork which, as it rocks, sends an impulse to the balance wheel. This causes the balance wheel to swing back and forth on its staff.

Specifically, as the pallet fork rocks, the end with the arms alternately locks and releases the escape wheel while the forked end sends an impulse to the balance wheel which swings back and forth as the balance spring contracts and expands. These two movements are interdependent: the escape wheel maintains the swinging motion of the balance wheel and the balance wheel determines the rate at which the escape wheel advances. Like a metronome counting the beats, the regulator releases energy in regular portions which determine the movement’s precision.

Time display

The regulator therefore sets the pace of a mechanical movement. The to and fro motion (or oscillation) of the balance wheel determines the speed at which the escape wheel rotates and, in turn, the speed at which the wheels carrying the hands rotate.

In pursuit of precision

As we’ve seen, a mechanical watch is equipped with an ingenious movement and each component of this movement has a specific function. Like any machine, a watch movement sometimes doesn’t operate perfectly. This can be due to the small size of its components: the balance spring, for example, is no thicker than a human hair. Also, friction and wear can cause power to be lost as it travels through the wheel train. Problems can arise too if the movement hasn’t been properly adjusted - and we are talking microns. For all these reasons, building a mechanical movement that precisely measures time is a challenge watchmakers have been working on for centuries, and one that has produced countless innovations. The ultimate goal, that of extreme precision, is in the hands of the Contrôle Officiel Suisse des Chronomètres (COSC). For a mechanical movement to be COSC-certified, it must demonstrate precision of -4/+6 seconds per day. In other words, it cannot lose more than four seconds or gain more than six seconds in twenty-four hours.